Used Forklift Buying Guide

Whether you need a forklift for small or heavy-duty jobs, you can find a used option that fits your needs. Read on for more about the advantages and disadvantages of buying a used forklift, what to check when buying a used forklift, the top components you should inspect, and whether you should purchase a used forklift from a private individual.

Tips for Buying a Used Forklift

When you’re in the market for a used forklift, remember the following tips:

- To save on delivery costs, look for a local forklift dealer.

- Request the full-service history, and look for discrepancies between the hour meter and the service book.

- Ensure the dealer offers a warranty.

- Check for any visible signs of damage due to negligence or wear and tear.

- Don’t take the forklift for a test drive and assume it’s in good condition — do a thorough inspection before you consider purchasing.

Advantages of Buying a Used Forklift

There are numerous benefits of buying a used forklift. Check them out below.

Save Money

Used forklifts are generally more affordable than their new counterparts, and they can still offer a great return on investment if used properly. Before purchasing, consider the following:

- What it will haul

- The distance it needs to carry loads

- Whether it’s suitable for indoor or outdoor use

- How much it needs to carry

- How often you’ll use it

Investing in a forklift that meets these needs helps ensure it lasts for the duration of its life span. Misuse of a forklift could shorten its life span, which could sour your great investment. You can also save money by purchasing a used model that comes with attachments.

Enjoy Easier Maintenance

A used forklift in good condition should come with a service and maintenance history that is accurate and current, making it easier for you to keep up with preventive maintenance down the line.

Ensure Faster Delivery

New forklifts have a longer lead time than used ones, so you’ll be able to fetch your used model or have it delivered sooner than you’d wait for a new one to be manufactured and delivered. This is essential if you’re trying to meet project deadlines and can’t afford to wait too long.

Get Brand Familiarity

Operating a new forklift can come with challenges. New models sometimes have features that require additional training, which takes up time. Older, used models are familiar and easier for experienced employees to operate, saving time and money on training costs.

Disadvantages of Buying a Used Forklift

As with any item that depreciates in value, there are some disadvantages of buying used forklifts. Let’s review a few.

Wear and Tear

While on the search for a used forklift, you may come across visible wear and tear that leaves the forklift in a less-than-satisfactory condition. Some of it could be superficial and not hinder the forklift’s performance, but other damage may be deeper and unseen. Some problems you could encounter include:

- Mast failure, which may lead to the forks malfunctioning.

- Faulty steering and switches.

- Problems with the fuel system — like dirt clogging — which could affect the hydraulic pump.

- Spent suspension and tires due to consistently carrying heavy loads.

- Engine overheating due to radiator or thermostat issues.

Undisclosed Issues

If you buy a used forklift from a private seller, you might encounter problems that weren’t initially disclosed. This often happens with third-party sellers who don’t offer a warranty but sell goods at a decent price to convince customers that it’s a deal they can’t miss. Without a warranty, you’ll be liable for any damages, which could become costly.

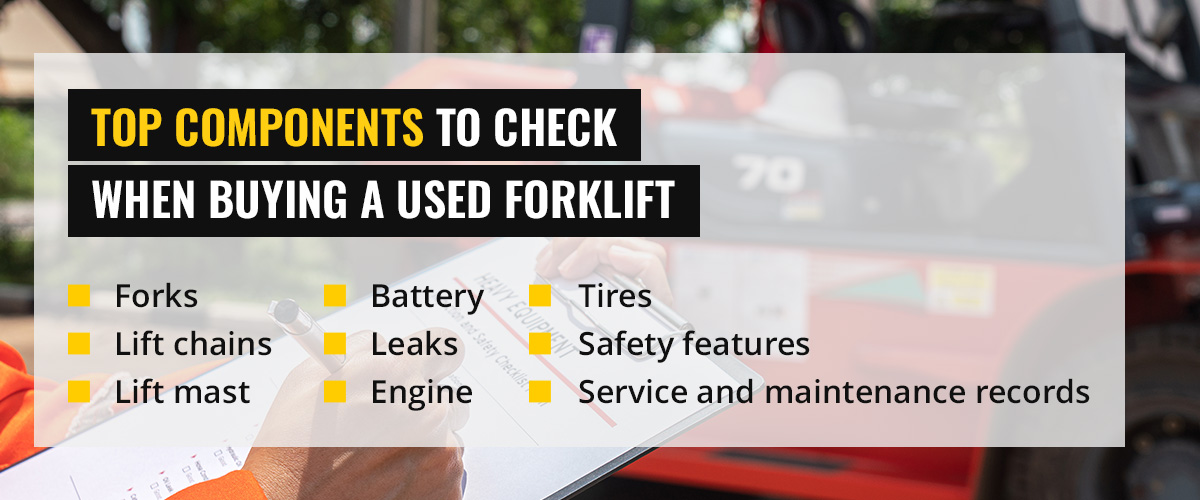

Top Components to Check When Buying a Used Forklift

When inspecting the components of a used forklift, enlist the help of an experienced mechanic if you aren’t experienced yourself. Here’s what to check when buying a used forklift:

- Forks: Since they’re the most used components, check the forks for signs they need to be replaced, like bends and cracks. The fork blade heel should be as thick as the upright fork shank for it to be in optimal condition.

- Lift chains: The lift chains are under immense pressure to lift the forks as they hoist loads, which often leads to cracks in the chains. Visible welding marks are signs of previous lift chain repairs. If done poorly, these repairs could weaken the mast and damage the forklift.

- Lift mast: The mast can be lifted and inspected from underneath. Any issues with the forks raising may be due to damaged link chains or worn mast rollers. Improperly maintained or unlubricated rollers can also cause damage.

- Battery: Check to see how old the battery is and whether there are signs of corrosion due to acid leakage. A battery that’s worn and old should be replaced before you purchase the forklift. Also, check the odometer to see how much mileage is left and to ensure it wasn’t tampered with.

- Leaks: Leaks located at certain points could signal damage, specifically in the mast cylinders, transmission, and radiator. Make sure to identify the source, as a leak could lead to bigger problems if left unattended.

- Engine: The engine works hard to keep the forklift running, so wear and tear is more likely to occur. Check the engine compartment, inspect the hoses for cracks, check the dipstick for enough oil, and inspect the belts for cracks due to a lack of lubrication.

- Tires: Forklift tires are expensive to replace, so they should be evaluated for their condition before purchasing. Chunking, punctures, cracks, low tread, and worn wear lines are all signs of damage that indicate the tires should be replaced.

- Safety features: All safety features must be examined since they keep the operator secure. These include the guard frame, levers, brakes, seats, seatbelts, and all the lights.

- Service and maintenance records: Clear and precise service and maintenance records must be presented before purchasing a forklift. Additionally, inspect the warranty, and request to see the Certificate of Thorough Examination to ensure adherence to the Provision and Use of Work Equipment Regulations (PUWER) and Lifting Operations and Lifting Equipment Regulations (LOLER).

Should You Buy a Used Forklift From a Private Individual?

Buying a used forklift from an individual might seem tempting, but there are drawbacks to consider. These include:

- Insufficient documents: A private seller may lack documents like a warranty and Certificate of Thorough Examination. Without these, you run the risk of spending more on repairs, and your forklift resale value will drop.

- Increased risk of fraud: Since you don’t know the history of the used forklift, you risk buying a faulty or damaged vehicle that you won’t be able to return after the sale is finalized. There’s also a chance that any documents may have been falsified, especially if you don’t know the seller personally.

A reputable dealer will provide you with current, certified paperwork that is reflective of the forklift’s condition.

Contact Thompson Lift Truck for Certified Used Forklifts

You want peace of mind when buying a used forklift, and Thompson Lift Truck can provide it. Thompson Lift Truck has certified used forklifts fit for any job, big or small. Our range of internal combustion and electric forklifts can be used for numerous applications, are cost-effective, have undergone thorough inspections and performance tests, and come with standard warranties before you use them.

If you need a used forklift to get a project done soon, request a quote today.