Forklift Extensions Guide

Forklift extensions have emerged as invaluable tools that elevate the capabilities of forklifts, allowing professionals to handle a diverse range of loads easily. This guide explores several types of forklift extensions and their unique features, applications, and advantages. From telescopic boom extensions to blade and fork extensions, each extension serves specific material handling needs and offers distinct benefits.

Types of Forklift Extensions

By leveraging each extension type’s unique features and advantages, you can optimize your material handling operations for improved efficiency, safety, and load-handling capabilities. Let’s look at three types of forklift extensions, delving into their unique features, applications, and advantages.

Forklift Boom Extensions

Forklift boom extensions, also known as telescopic boom extensions or jib attachments, extend the reach and versatility of forklifts in material handling operations. These heavy-duty forklift extensions handle long, bulky, or heavy loads that are challenging to manage with standard fork installations alone. Here are the features of forklift boom extensions:

- Adjustable length: Forklift boom extensions feature telescopic arms that can be adjusted to various distances, allowing operators to extend the forklift’s reach based on the specific load or material handling requirements.

- Load capacity: Depending on the model and design, forklift boom extensions can support significant weight capacities, enabling the safe and efficient handling of heavy loads, such as steel beams, lumber, pipes, or construction materials.

- Versatile applications: Forklift boom extensions find applications in various industries, including construction, manufacturing, warehousing, and logistics. They are ideal for handling long or irregularly shaped items that would be challenging to lift with standard forks.

- Improved maneuverability: Forklift boom extensions allow for greater maneuverability, especially in confined spaces or areas with limited overhead clearance. The adjustable boom arms give operators better control during the lifting and positioning loads.

- Load balancing mechanism: Many forklift boom extensions have load balancing mechanisms, ensuring stability during lifting and transport. This feature helps prevent load tipping and maintains load integrity, contributing to safer material handling practices.

Forklift operators can utilize this attachment in various applications, such as the following:

- Construction: In the construction industry, forklift boom extensions are often used to lift and place materials such as steel beams, roof trusses, and concrete forms at elevated heights, streamlining building processes.

- Warehousing: Forklift boom extensions are valuable in warehouses for handling items with extended dimensions, including piping, tubing, and other long items that may not fit on standard pallets.

- Freight handling: In logistics and freight industries, forklift boom extensions are employed to efficiently load and unload oversized or heavy freight items from trailers and containers.

- Roofing: Forklift boom extensions are widely used in the roofing industry to lift bundles of shingles or other roofing materials to elevated locations, minimizing manual labor and expediting the roofing process.

Forklift Blade Extensions

Forklift blade extensions, also known as tine extensions or pallet extensions, are attachments that enhance the capabilities of forklifts when handling larger or non-standard pallets and loads. These extensions allow forklifts to safely and efficiently handle wider and heavier loads that exceed the capacity of standard forks. Forklift blade extensions provide various benefits, including the following:

- Increased load capacity: Heavy-duty forklift blade extensions provide additional support and stability when lifting heavier and bulkier loads by extending the length of the forklift forks.

- Load stability: Forklift blade extensions have a secure clamping system that attaches them firmly to the existing forks. This feature ensures load stability during lifting and transport, preventing loads from slipping or becoming unbalanced.

- Adjustable length: Many forklift blade extensions are designed with adjustable range, allowing operators to customize the extension’s size based on the load dimensions and weight requirements.

- Pallet handling: Forklift blade extensions are helpful when dealing with specialized or oversized pallets that do not fit within the confines of standard forks. They provide the necessary support to safely handle materials like lumber, sheet metal, or machinery.

The applications of the forklift blade extensions are as follows:

- Manufacturing: In manufacturing facilities, forklift blade extensions move oversized machinery parts or large crates, streamlining production processes.

- Metal fabrication: In metal fabrication industries, forklift blade extensions are employed to easily lift and transport large sheets of metal or heavy metal components.

- Transportation: Forklift blade extensions load and unload trailers or containers that house non-standard pallets or irregularly shaped freight.

Forklift Fork Extensions

Forklift fork extensions are attachments that extend the length of the forks, providing increased reach and load-carrying capacity. These extensions are versatile tools that allow forklift operators to handle longer or wider loads that would be challenging to manage with standard forks alone. The following are a few advantages that come with fork extensions for forklifts:

- Increased load capacity: Forklift fork extensions support heavier loads than standard forks. By extending the fork length, they distribute the load weight more effectively, allowing for the safe and stable lifting of bulkier or heavier materials.

- Easy installation: They slide over the existing forks and are secured with safety pins or retention straps, providing a secure and reliable attachment.

- Versatility: Forklift fork extensions find applications in various industries, including construction, manufacturing, warehousing, and shipping. They are handy when handling long pipes, lumber, steel bars, or large crates.

This extension can be useful in the following applications:

- Manufacturing: In manufacturing facilities, forklift extensions help move oversized machinery components or handle large crates and containers.

- Shipping and freight handling: Forklift fork extensions also help efficiently load and unload trailers and shipping containers that house longer or wider loads.

- Agriculture: Forklift fork extensions are beneficial in agricultural settings, where they assist in handling large bales of hay or other farm equipment.

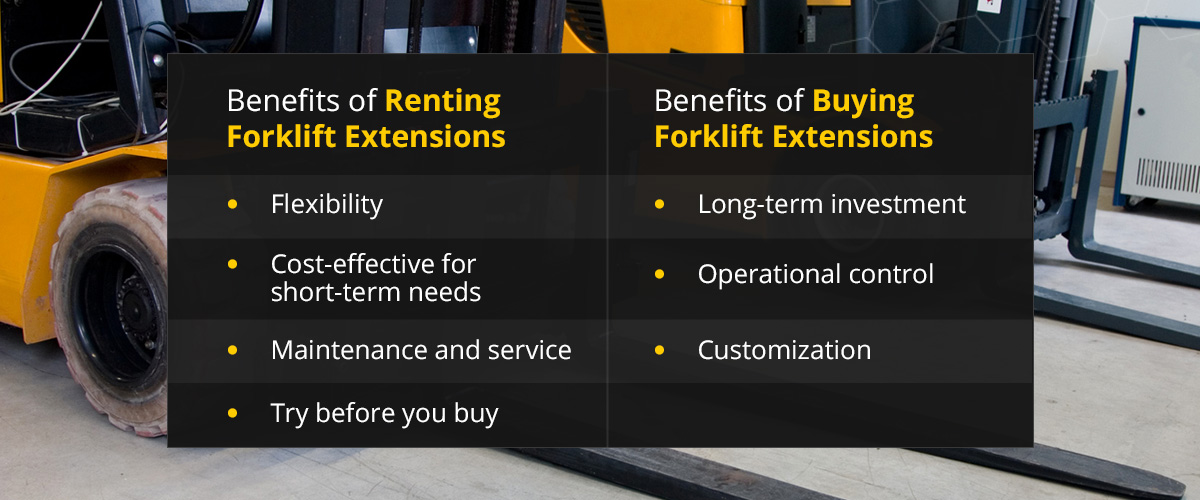

Should I Rent or Buy Forklift Extensions?

Both options have their merits, and choosing the most suitable approach depends on several factors. Learn about the advantages and considerations of renting and buying heavy-duty forklift extensions to help you make an informed decision that aligns with your specific needs and operational requirements.

Renting Forklift Extensions

Here are a few advantages of renting forklift extensions:

- Flexibility: Renting forklift extensions offers the flexibility to adapt to varying workload demands and changing material handling requirements. You can easily add or remove extensions based on your projects or tasks.

- Cost-effective for short-term needs: If your need for forklift extensions is occasional or short-term, renting is often more cost-effective than investing in purchasing them.

- Maintenance and service: Maintenance and service are typically included in the rental agreement when renting forklift extensions. This saves you the hassle of handling repairs and ensures the extensions are in optimal condition for each use.

- Try before you buy: Renting forklift extensions allows you to evaluate their performance and suitability for your operations before making a long-term commitment. The “try before you buy” approach can help you make an informed decision when considering future purchases.

Buying Forklift Extensions

Now that we have looked at the benefits of renting, let’s examine the advantages of buying:

- Long-term investment: Purchasing forklift extensions is a long-term investment that can provide a cost-effective solution for consistent and regular material handling operations.

- Operational control: Owning forklift extensions gives you complete operational control, allowing you to use them whenever and wherever needed without limitations or time constraints.

- Customization: Purchasing forklift extensions enables you to select the extensions that precisely match your material handling requirements, including size, capacity, and specialized features.

Contact Thompson Lift Truck for Your Forklift Extension Needs

Whether you opt for the flexibility and cost-effectiveness of renting or the long-term benefits and operational control of buying, our expert team is committed to providing the right solution to elevate your material handling capabilities. As experienced professionals, we comprehend the importance of aligning your investment with your business objectives and financial considerations.

Choose Thompson Lift Truck Solutions, and let us empower your material handling operations with the perfect forklift extensions. With our expertise, dedication and comprehensive solutions, you can rest assured that you are making a decision that will drive success and efficiency in your material handling endeavors. Request a quote for your forklift today.