How to Charge an Electric Forklift Battery

Need Advice about Charging Your Electric Forklift?

Electric forklifts are efficient and low-maintenance; however, charging them correctly is key to keeping the battery healthy and maximizing forklift performance. This guide explains how to charge electric forklifts, how long it takes, and when to recharge, based on battery type.

How Long Does It Take to Charge a Forklift Battery?

Charging time depends on the battery and charger type:

- Lead-acid batteries: Typically take 8 hours to fully charge. Requires 8 hour cool-down afterward.

- Lithium-ion batteries: 80% charge in 1-2 hours and a full charge in 2-4 hours. No cool-down needed.

- Thin Plate Pure Lead (TPPL): Use opportunity charging. Can charge from 40% to 80% in about 1 hour and full charge in 1.5 to 5 hours, depending on usage.

- Fast charge systems: Can deliver a partial charge in as little as 15 minutes. Only safe with compatible batteries and chargers.

How long to charge a forklift battery varies by use case, so check your manufacturer’s guidance.

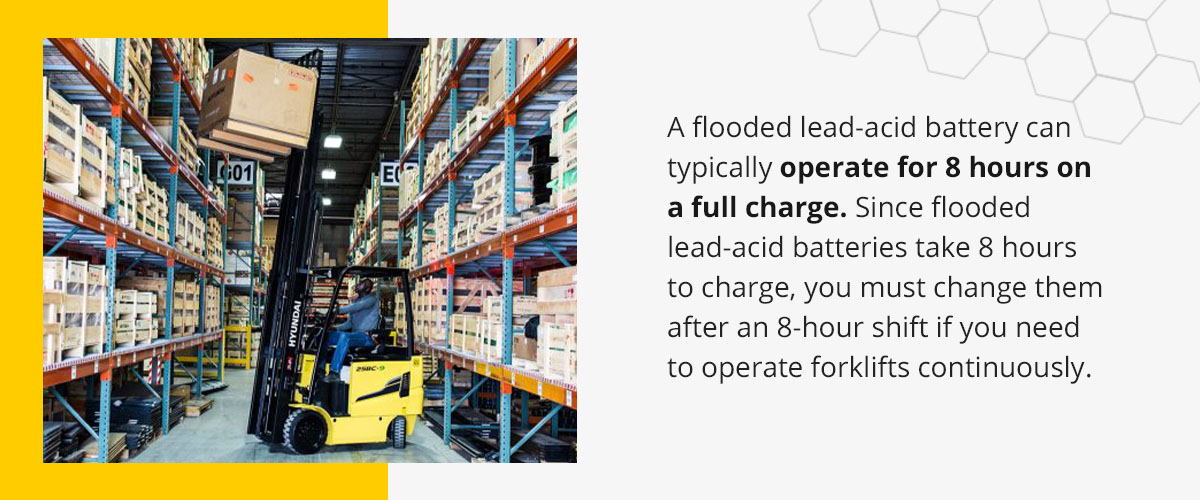

How Long Do Electric Forklifts Run on One Charge?

Most electric forklifts run for 8 hours on a full charge.

Battery size, voltage, and how the forklift is used can impact run time. Keeping the battery clean and matched to the forklift’s specs helps maximize operating time.

When Should Electric Lift Truck Batteries Be Charged?

Electric Forklift batteries should be recharged when they reach about 20%–30% capacity.

Never let them fully discharge.

- Use overnight charging for lead-acid batteries

- Lithium-ion can charge during breaks or between shifts

- TPPL batteries work best with frequent opportunity charging

Electric lift truck batteries should be charged before they fall below safe operating thresholds.

Forklift Charging Stations: What You Need to Know

Set up a safe, compliant forklift charging station with:

- Fire extinguisher

- Acid neutralization kit

- Ventilation system

- No-smoking signage

- Safety shower and eyewash station

- Acid-resistant flooring

Make sure your charger matches your electric forklift battery’s voltage and amp-hour rating.

Types of Electric Forklift Batteries

| Type | Charge Time | Notes |

|---|---|---|

| Lead-acid | 8 hrs | Needs watering, cool-down required |

| Lithium-ion | 1–4 hrs | Fast, low maintenance |

| TPPL | 1–5 hrs | Frequent top-ups, no need to swap |

Purchase High-Quality Electric Forklifts From Thompson Lift Truck

Electric forklifts are excellent machines, and charging your forklift battery properly can increase its longevity. Some forklifts charge rapidly and offer 8 hours of run time, while others require more detailed charging scheduling.

Thompson Lift Truck offers high-quality electric forklifts to help you increase your efficiency and productivity.

FAQs About Charging Electric Forklifts

How do you charge electric forklifts?

Plug the forklift into an approved charger in a ventilated space. Turn it off and let the battery fully charge before use.

What are the charging requirements for electric forklifts?

Use the correct charger, voltage, and a ventilated area. Lead-acid needs watering; lithium and TPPL require less maintenance.

Is it safe to charge an electric forklift overnight?

Yes, as long as you use a smart charger and follow safety guidelines. Ensure the charging area is up to code.

How long does it take to charge an electric forklift?

Lead-acid: 8 hrs. Lithium-ion: 1–4 hrs. TPPL: 1–5 hrs. Charging time depends on the battery type.

How often should you charge an electric forklift battery?

Charge when the battery reaches 20% to 30%. Avoid charging too often or waiting until it’s too low.

Can you overcharge a forklift battery?

Yes. Overcharging can cause heat damage and acid leaks. Always use a compatible smart charger.

Should you add water before or after charging a forklift battery?

Only add water after charging and cooling. Topping up before can cause acid overflow and safety risks.